The SPX panel system combines air-tightness and higher thermal insulation to achieve the highest thermal efficiency of any housing technology. This is ideal for designing to a Zero or Near Zero Energy standard.

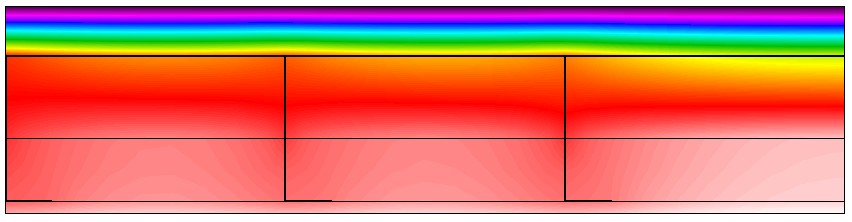

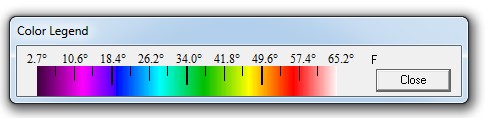

Heat is lost through a wall from conduction through the materials, and convection from the flow of air through a wall system. Combined these heat losses account for over 60% of your energy bill.

To address conduction, we use a total R-value of R39 to resist 97% of the heat loss from conduction (any more insulation is not economical). We use an exterior insulation of R15 to prevent thermal bridging losses, and R24 interior cavity insulation.

To address convection losses, the SPX provides a complete metal diaphragm and external vapor barrier to virtually make the wall system air-tight.

All SPX houses are modelled for heat loss estimates in order to size the heating and ventilation systems.

SIMPLE INSTALLATION FOR DIY AND PROFESSIONALS

A SPX wall system can be assembled by skilled homeowners or trades professionals. No certification is required, and the system only assembles one way. Panels are lightweight and do not need heavy or specialized equipment to erect.

Materials can be provided as components or in prefabricated panels to match your design. Basic tools to install the system include an impact drill gun, and abrasive cutoff grinder or saw. While projects can vary in complexity where it is better to get professional help, most projects are assembled by homeowners themselves. Make sure to follow saftey precautions.

HIGH STANDARDS GIVE YOU CONFIDENCE

The SPX Panel system was modelled by computer using advanced automotive design concepts, prototyped and tested to capacity. A SPX home is likely the strongest and safest system available. It has been tested to withstand over 560lbs per square foot without collapse - greatly surpassing the limits of the building code. Unlike other steel systems, we use higher strength steel than the building codes and our competition. The SPX system was then fire tested by Underwriters Laboratories under a 100,000 lb load and 1300 F fire, where the structure passed a 1-hour fire rating.

SPX has received certification from PEI (Unityed States) and UL Underwriters (Canada and United States).

SPX has unmatched warranties:

- 30 Year Warranty for structural capacity

- Lifetime Warranty against water penetration

Design Elegance

Whether you are planning a renovation or a new custom home, SPX can accomodate any existing or new design. Simply send us your existing drawings and we will provide an SPX quote. Design your look to suit your preference for design or budget.

Earth Friendly

SPX IS SUSTAINABLE and will not compromise future generations.

- Steel is the most recyled material in the world, more than all other materials combined.

- SPX™ structures are made from 95% recycled steel.

- SPX™ materials will never see a landfill or incinerator.

THE SUMMIT OF CONSTRUCTION TECHNOLOGY

TIMELESS • STRONG • SUSTAINABLE

Galvanized Steel Structural Panels

With the highest strength per unit weight of any construction technology, SPX resists settling in soft soils, and is able to support up to six floors above. SPX is the only unibody structural panel available. SPX is the only housing technology backed by a 30-year structural warranty.

With 50% more corrosion protection than required by code, SPX panels are designed to last over 200 years. With SPX, architects and designers have their chance to create enduring colourful designs for contemporary architectural projects.

SPX panels have a continuous exterior metal skin with built-in drainage planes to prevent moisture and air getting into the wall cavity. This prevents mold, ensures air-tightness and superior air quality. SPX is the only technology backed by a lifetime warranty against water penetration.

SPX panels are certified by Underwriters Laboratories for both structural capacity and fire safety. The first system to acvhieve this level of certification in North America.

The SPX panel system provides the ideal configuration for the perfect building envelope - protecting the inside from outside. The best place for the control layers is to locate them on the outside of the structure in order to protect the structure.

- A full metal exterior diaphragm. Similar to advanced automobiles and airplanes, SPX is a unibody construction design comprising a one-piece stud/diaphragm structure. This design is lighter and more rigid than a structure having a separate sheathing and a stick frame.

- Built-in drainage planes. The SPX panel has recessed forms to provide an additional drainage plane relieving any hydrostatic pressure that may develop against the wall, with moisture is redirected down and drained out the bottom.

- Exterior vapor barrier. Each overlapping panel is sealed to the one before with butyl tape, and the panel is further covered with an additional vapor barrier. The fundamental principle of control of water in the vapor form is to keep it out and to let it out if it gets in.

- Exterior insulation. A layer of insulation is added to the exterior to provide a thermal break from the steel. The amount of insulation depends on your climate and can range from R7 to R15.

- Interior Insulation. The interior cavity is also insulated to meet your thermal performance objectives. With minimal air infiltration and high thermal insulation, you can achieve a virtual net zero engery level of performance. With the wall cavity open to the interior, moisture is dried towards to the inside of the house.

The Perfect Building Envelope.

Protecting the inside from outside ensures the best air quality and thermal comfort of a home. When every part of a building enclosure works in sync, moisture problems are avoided and indoor air is of the highest quality.

Superior Thermal Performance.

R24 Interior Cavity Insulation

Available by Special Order At